Solving Environmental Problems through Mechanisms

Solving environmental problems requires not only a philosophy, but also ingenuity in technology and business models. We believe that a little wisdom goes a long way.

Pursuing a Sustainable Circulation Mechanism

A business model must be economically rational to be sustainable. We believe that focusing on continuity and scalability will lead to effective options.

Be the center of the mechanism

We will not stop at theoretical solutions, but will demonstrate our part in a recycling society as a manufacturer. We will lead by example and work together with our global partners to realize a recycling society.

ABOUT US

Sustainable Energy

We are an “eco-realization company” founded on the principle of “contributing to society from a global perspective with the aim of realizing a sustainable society. We focus on environmental technologies that are buried in the world and use them to commercialize our products. We will work steadily, starting from a small scope.

BUSINESS

Business Description

We are developing mainly the biomass fuel refining business derived from waste tire chips.

By utilizing large quantities of discarded resources and producing recycled fuels ourselves, we play a role in creating a recycling-oriented society and in addressing greenhouse gas emissions. By utilizing our proprietary technologies, we ensure economic rationality while realizing a sustainable business.

・We are engaged in the business of refining biomass fuel derived from waste tire chips.

・We are engaged in the business of refining biomass fuels derived from other waste materials and plants.

We aim to realize a recycling-oriented society faster by providing our expertise, which we have demonstrated in our renewable energy business, to external business partners such as corporations and municipalities.

・We provide solutions to companies and local governments that are building businesses using biomass fuels (business revitalization, town revitalization, etc.).

・Provide solutions to overseas partners.

Through innovation, we will create value in the form of new technologies and services, as well as reinvigorate existing businesses, to build a society that is safe and secure, high in quality and productivity, and capable of sustaining sustainable growth.

・We will provide risk capital to venture companies that are engaged in innovative and creative management, and support them in increasing their corporate value by committing to their management and business expansion.

・We will invest in innovative start-up companies in the environmental field and provide support to the investees.

Necessity of Waste Tire Recycling

Moving from thermal recycling, which is the mainstream method of waste tire treatment, to material and chemical recycling, which is what it should be.

Recycling as Heat Source Utilization

It is estimated that 97% of waste tires (used tires) are recycled, although approximately 100 million tires (about 1 million tons) are generated annually in Japan. This is comparable to the 94% recycling rate for aluminum cans, which are considered an excellent recycler. However, 65% of waste tire recycling is thermal recycling, meaning that the tires are crushed and incinerated. In Europe, thermal recycling is not recognized as recycling.

Recycling as Biofuel

Thermal recycling contributes to reducing landfill disposal and illegal dumping, but it is not the true form of recycling. In addition, the surplus of waste tires is increasing due to competition from other fuels derived from waste, declining usage by the paper industry, which is the center of the industry, and environmental impact issues. We believe that the most desirable solution to the increase in waste tires is to convert them into biofuel, which is currently almost completely out of practical use.

Background of our success in refining biomass fuel derived from waste tires

The “oilification” method of disposing of waste tires, including waste plastics, was part of a popular approach after the oil crisis. However, many companies entered the market but eventually withdrew from the market due to unprofitability, and it was concluded that the most economical way to use waste tires was to use them as a heat source. We overcame this economic barrier and for the first time came up with a realistic solution as a recycled fuel.

Improvement of oilification process

In the oilification process, oil is vaporized by heat treatment and cooled to produce crude oil. We have made time-consuming heat treatment more efficient, resulting in significant productivity improvements.

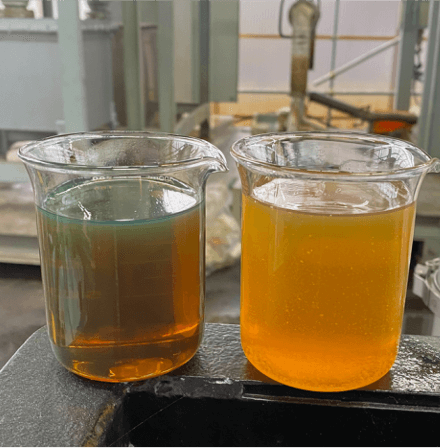

Improvement of refining process

We have successfully developed a catalyst technology to efficiently refine biofuels. At the same time, we have succeeded in detoxifying waste residues that would otherwise have become industrial waste to a level where they can be disposed of as ordinary combustible waste.

Improvement of refining equipment

Since the utilization of existing equipment was not sufficient for both oil converting and oil refining equipment, unique designs and improvements tied to the process were added to achieve the desired efficiency.

Ingenuity as a business

The utilization of waste tires, which contain a large heat source and are mainly composed of natural rubber, was necessary in a recycling-oriented society, but there were limits to the demand for simply cut tire chips. We thought that commercialization of biofuel, for which much demand existed, within economic rationality would be the key to commercialization.

Environmental Changes

In addition to the problem of surplus waste tires, the demand for more environmentally conscious use of waste tires has greatly increased the demand for biofuels that are economically rational for general businesses.

Collaboration

Returnable is a business development company that focuses on environmental technologies that are buried in the world and seeks to commercialize them using those technologies. It is not bound by investment periods or yields like a fund, but works as its own business. We are convinced that the fusion of a company specializing in technology and a business development company will lead to the creation of new businesses.

Returnable Co., Ltd.

Recent Topics